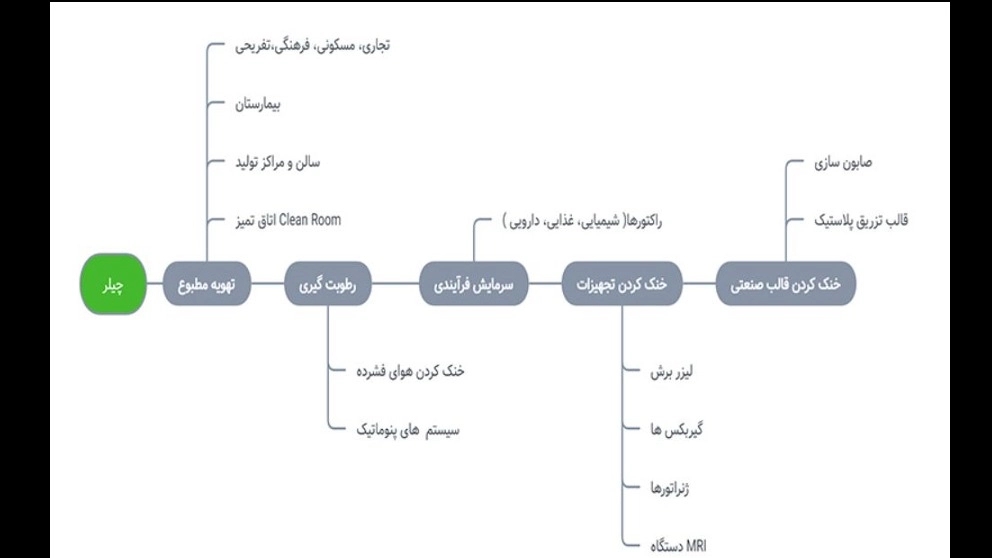

As we said, the main task of this product is to provide water cooling, to keep the air cool in the building or for industrial use. In general, chillers are used for two types of applications: Industrial chiller (industrial cooling)

In fact, by using this product, you can use all the activities that need cooling, such as factory machines and industrial and production items. Industrial chillers can exchange heat between fluids on a large scale. These devices are a portable cooling system that is why they are widely used in factories. In other words, industrial chillers play the role of a refrigeration system. The most common use of chillers in the industry is to cool production devices. Note that industrial chillers do not cool anything, but remove the existing heat, which eventually cools the environment. In industrial use, cold water or any other cold fluid can be provided by this chiller. Industrial chillers are mostly used to cool products and machines in a wide range of industries. air conditioning

In fact, for cooling homes or places such as passages, using air conditioning, the cold water produced by the chiller is transferred to the fan coils or air conditioners so that cold air flows. The industrial chiller device is considered as a subset of the air conditioning system. In the air conditioning system of buildings, usually the cold water produced in the cold supply equipment is introduced into the heat exchanger or the air conditioning coil, to cool the air flowing over the coil. The cooled air is transferred directly or through the channel to the desired space that needs to be cooled. Then the cold water or the refrigerant fluid that has been heated in the coils during the mentioned process circulates in the system until it is cooled during the refrigeration cycle and enters the cycle again. In air conditioners, latent and sensible heat is transferred from air to circulating water. Therefore, in this way the air and humidity of the room is controlled. Air conditioning chillers are used in different tonnages of refrigeration to provide cooling. The output cold water temperature of this cooling equipment varies between 1.5 and 7 degrees Celsius according to its needs and application. Working method of industrial chiller

Chillers do cooling by using an absorption or combined cycle. Actually, the refrigerant fluid is first compressed while passing through the combined cycle, then it loses some heat by passing through the condenser, and after passing through the pressure relief valve, its temperature increases and it turns into vapor. In the absorption cycle, similar to the combined cycle, first the refrigerant evaporates and after passing through the condenser and pressure relief valve, it drops. It is repeated. What is refrigeration?

Cooling or refrigerating the environment is reducing the temperature or adjusting it. In other words, refrigeration means reducing the temperature of the environment using heat transfer from one environment (substance) to another environment (substance) whose temperature is higher. Chillers are divided into the following three categories according to the way the refrigerant is cooled:

Cool water chiller (Water Cooling Tower) This type of chiller is a cold generator that is used as a summer air conditioner to cool industrial and process equipment. In fact, by producing cold water, it creates the necessary cooling for industrial devices, air conditioners, fans. Air Cooled Chiller Air-cooled chillers use the fan directly. In fact, in this model, cooling is produced through the condensation (evaporation) cycle. Evaporative

How to choose a chiller

In choosing the right chiller, the following parameters should be considered:

The place where the device wants to be installed

Energy consumption and its availability in the region

Atmospheric and climatic conditions of the installation location (climate, temperature and relative humidity)

The amount of cost that should be considered for repairs and service of its equipment

Installation costs

Required cooling capacity

The type of equipment and parts used in the chiller device

Iranian or foreign chiller brand

coefficient of performance

Advantages of chiller

Chiller advantages; It saves electricity. The biggest advantage of these products is saving electricity. These devices consume little electricity, which is why they are used to cool large environments. Chiller advantages; Consumption of diesel in absorption chiller

Also, instead of electricity consumption, absorption chillers use diesel or natural gas and ambient heat as fuel, and the amount of electricity consumption of these types of chillers is very low. Chiller advantages; Very low maintenance cost Chillers have a very low maintenance cost and the electrical power they release can be used for lighting. Chiller advantages; Use of chiller in winter Another thing that distinguishes chillers from similar devices is the possibility of using them in winter. You can use some absorption chillers as heaters. In fact, chillers can provide hot water needed for heating devices. However, chillers are usually used as the cooling system of residential buildings. Unlike other cooling systems that produce a lot of noise, chillers do not have this problem.